Home

Products

Crushers

Screening

Washing

Handling

Mobile Solutions

Fixed Plants

Additionals

Corporate

Videos

Jaw Crusher

Primary Impactor

Secondary Impactor

Reversible Impactor

Vertical Shaft Impact

Cone Crusher

Hammer Crusher

Roll Crusher

Control System

Spare Parts

Ready from Stock

About Us

Contact

Our Dealers

Blogs

Inclined Screen

Horizontal Screen

Grizzly Screen

Screw Washer

Bucket Washer

Log Washer

Loading Bunker

Feeding Hopper

Intermediary Hopper

Fixed Conveyor

Radial Conveyor

Mobile Jaw

Mobile Impactor

POWERCRUSH-I

POWERCRUSH-C

Mobile VSI

Mobile Cone

Mobile Screening

Mobile Screen-Wash

Catalog

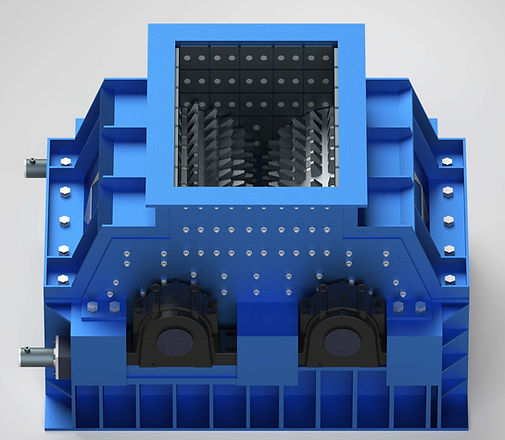

SRC series

Roll Crusher

A roll crusher is a machine used to crush materials by compressing them between two rotating cylindrical rolls. The rolls rotate in opposite directions, pulling the material through and breaking it down into smaller, uniform-sized particles. Roll crushers are widely used in mining, metallurgy, chemical, and building materials industries for secondary and fine crushing of medium-hard to hard materials.

WORKING PRINCIPLE OF THE ROLL CRUSHER

** The basic construction of a roll crusher typically includes two parallel cylindrical rolls mounted on a frame, rotating towards each other.

** The material is fed between the two rotating rolls through a feed opening.

** As the rolls rotate in opposite directions, they pull the material in and crush it by compressive force between the rolls.

** The crushed material size is controlled by the gap or distance between the two rolls.

** The crushed material passes through the gap, with finer particles exiting freely, while larger particles remain for further crushing.

USAGE OF THE ROLL CRUSHER

** Roll crushers are valued for their ability to crush medium-hard to hard materials with a consistent and uniform particle size.

** They are commonly used for secondary and fine crushing of materials such as coal, ore, limestone, clay, and other minerals.

** Roll crushers come in various sizes and configurations, including single-roll and double-roll designs, with smooth or toothed rolls depending on the crushing requirements.

** Some advantages of using a roll crusher include low dust generation, relatively low noise, energy efficiency, and the ability to produce a controlled particle size with minimal fines.

--- TECHNICAL DETAILS TABLE ---

A | B | C | D | E |

|---|---|---|---|---|

MODEL | ROTOR DIMENSIONS | CAPACITY | MOTOR POWER | ADJUSTMENT RANGE |

SRC 0604 | 610 x 405 mm | 15-95 tph | 30 kW | 6-38 mm |

SRC 1005 | 1016 x 558 mm | 35-350 tph | 75 kW | 6-76 mm |